Comparison of DVF 5000 1st Generation and DVF 5000 2nd Generation

With the introduction of the DVF 5000 2nd Generation, DN Solutions has taken their popular 5-axis machining center to the next level. In this article, we highlight the key differences between the original DVF 5000 and the new 2nd Generation model.

Improved Performance and Precision.

The DVF 5000 1st Gen is known for its precision and reliability, featuring a standard maximum spindle speed of 12,000 RPM and a standard table diameter of 500 mm. The machine is ideal for complex workpieces that demand high precision.

The DVF 5000 2nd Gen builds on this foundation and introduces several enhancements:

- Increased Spindle Speed: The standard spindle is of the built-in type with 230 Nm high torque and now offers 15,000 RPM.The built-in spindle allows for an increase in RPM up to 20,000, enabling better surface finish and machining of a wider range of materials such as aluminum, titanium, and Inconel.

- Larger Work Area: The X/Y/Z axis travels have been extended to 650 mm, 520 mm, and 480 mm, respectively.

- Speed Up: The rapid traverse and feedrate of the X/Y/Z axes have increased to 42 m/min.

- Improved Rotation Speed: The rotational speeds of the B- and C-axes have increased by 25%, reaching 25 RPM, which reduces cycle times and increases productivity.

- Faster Tool Change: Tool-to-tool time has been reduced to 1.5 seconds, and chip-to-chip time is now 4.3 seconds at 60Hz.

Increased Automation and Production Flexibility.

The DVF 5000 2nd Gen is designed with automation in mind:

- Larger Table: The table diameter has been increased to 630 mm, allowing machining of larger parts up to Ø600x500 mm.

- Expanded Tool Magazine: The machine supports up to 120 tools, reducing the need for tool changes and increasing efficiency. Tool changes now occur from the machine's front.

- Improved Chip Removal: With new types of chip conveyors and additional coolant nozzles, bed flushing coolant has been significantly improved.

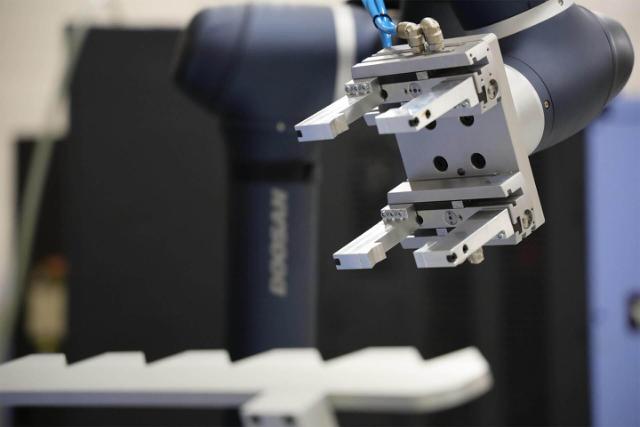

- Integrated Automation: Option for integration of Auto Workpiece Changer with up to 40 pallets (AWC) and a Round Tool Magazine with capacity for up to 300 tools, making the machine suitable for unmanned operation and high-volume production

Advanced Thermal Stability.

To ensure consistently high precision, the DVF 5000 2nd Gen is equipped with:

- Symmetrical Machine Structure: Designed to minimize deformation and ensure stability during machining.

- Standard Thermal Compensation: Ensures accuracy even during extended operations. Additionally, temperature is monitored at 11 measurement points – including guides and ball screws.

While the original DVF 5000 is already a strong solution for precise 5-axis machining, the DVF 5000 2nd Generation offers significant improvements in speed, capacity, and automation.

For companies looking to optimize their production with advanced technology and increased efficiency, the latest generation is an obvious choice.

Contact us

If you have any questions regarding the DVF 5000 2nd generation, don't hesitate to contact us.

Comparison of DVF 5000 1st Generation and DVF 5000 2nd Generation

With the introduction of the DVF 5000 2nd Generation, DN Solutions has taken their popular 5-axis machining center to the next level. In this article, we highlight the key differences between the original DVF 5000 and the new 2nd Generation model.

CNC milling machines with collaborative robots strengthen your competitiveness

Do you often solve tasks in the same way either because it works or maybe because that's the way you've always done it?