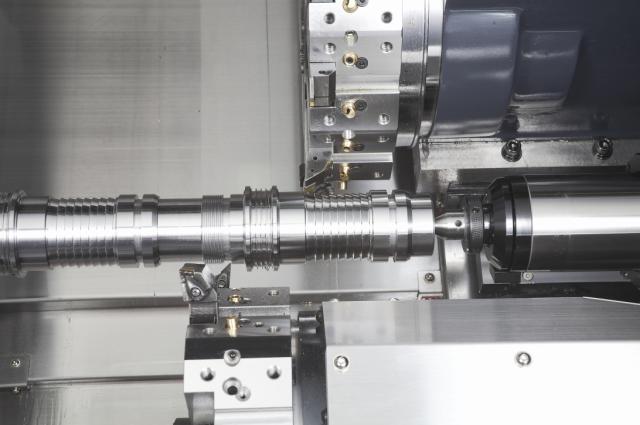

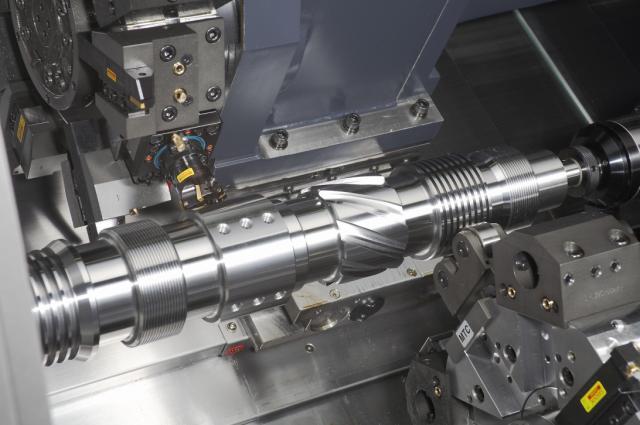

PUMA TL2500L

- High Efficiency: The PUMA TL series is engineered to maximize productivity through highly efficient machining processes.

- Integrated Performance: Designed as a process-integrated machine, it offers seamless operations that enhance overall production capabilities.

- Best-in-Class Machining: Delivers top-tier machining performance, providing customers with exceptional precision and reliability in their manufacturing processes.

Highlights

- Travels - X Axis Travel distance (mm): 250

- Travels - Z Axis Travel distance (mm): 1050

- Chuck size (mm): 255

- Max. Turning Diameter (mm): 370

- Max. Turning Length (mm): 1000

Series description

|

The PUMA TL2000/2500 series is designed to enhance productivity through high-efficiency machining. As a process-integrated machine, the PUMA TL series offers exceptional performance and best-in-class machining capabilities, making it ideal for industries requiring reliable, high-precision production. These machines are engineered to deliver new levels of operational efficiency, ensuring that customers achieve optimal results in their manufacturing processes. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 250 |

|---|---|

| Travels - Z Axis Travel distance (mm) | 1050 |

| Travels - X Axis Rapid Traverse (m/min) | 20 |

| Travels - Z Axis Rapid Traverse (m/min) | 24 |

Tool storage capacity

| Machining center - No. of tool station | 12 |

|---|

Capacity

| Chuck size (mm) | 255 |

|---|---|

| Max. Turning Diameter (mm) | 370 |

| Max. Turning Length (mm) | 1000 |

| Bar Capacity (mm) | 76 |

Main spindle

| Main Spindle Max. Speed | 4000 |

|---|---|

| Main Spindle Max. Power | 26 |

| Main Spindle Max. Torque | 433 |

Turret

| Turret - No. of tool station | 12 |

|---|

Dimensions

| Length (mm) | 3250 |

|---|---|

| Height (mm) | 1930 |

| Width (mm) | 2118 |

| Weight (kg) | 7300 |

| Name | Download | File type | |

|---|---|---|---|

|

PUMA_TL.pdf | 7544 KB | |

|

TOOLING SYSTEM-PUMA-TL-2000-2500.pdf | 444 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |

Contact us

If you have any questions, don't hesitate to contact us.