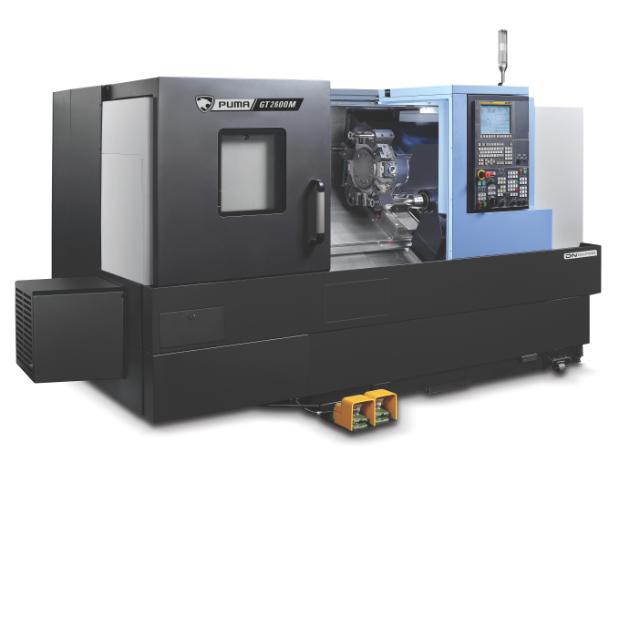

PUMA GT2600XLB

- Unmatched Spindle Power: The series offers the most powerful spindle in its class, delivering superior machining capabilities.

- Precise and Efficient Machining: The innovative tool post design ensures accurate and efficient cutting, boosting overall productivity.

- User-Centric Design: Focuses on convenient operation and easy maintenance, enhancing operator comfort and minimizing downtime.

Highlights

- Travels - X Axis Travel distance (mm): 265

- Travels - Z Axis Travel distance (mm): 1625

- Chuck size (mm): 315

- Max. Turning Diameter (mm): 460

- Max. Turning Length (mm): 1573

Series description

|

The PUMA GT Series comprises turning centers with 8, 10, and 12-inch chuck sizes, setting new global standards for performance. Featuring the most powerful spindle in their class and an innovative tool post design, these machines ensure powerful, precise machining and exceptional productivity. The GT Series is designed for user-friendly operation and easy maintenance, making it ideal for high-efficiency machining tasks. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 265 |

|---|---|

| Travels - Z Axis Travel distance (mm) | 1625 |

| Travels - X Axis Rapid Traverse (m/min) | 24 |

| Travels - Z Axis Rapid Traverse (m/min) | 30 |

Tool storage capacity

| Machining center - No. of tool station | 10 |

|---|

Capacity

| Chuck size (mm) | 315 |

|---|---|

| Max. Turning Diameter (mm) | 460 |

| Max. Turning Length (mm) | 1573 |

| Bar Capacity (mm) | 102 |

Main spindle

| Main Spindle Max. Speed | 2500 |

|---|---|

| Main Spindle Max. Power | 22 |

| Main Spindle Max. Torque | 992 |

Turret

| Turret - No. of tool station | 12 |

|---|

Dimensions

| Length (mm) | 4960 |

|---|---|

| Height (mm) | 2030 |

| Width (mm) | 2198 |

| Weight (kg) | 6050 |

| Name | Download | File type | |

|---|---|---|---|

|

PUMA_GT2600.pdf | 6131 KB | |

|

TOOLING SYSTEM-PUMA-GT-2100-2600-3100.pdf | 645 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |

Contact us

If you have any questions, don't hesitate to contact us.