DEM 4000

- High Rigidity: Robust structure ensures stability and precision during machining operations.

- Optimized Performance: Designed to deliver essential capabilities for effective 3-axis general machining.

- Versatile Application: Ideal for a wide range of basic cutting processes, offering reliable performance.

Highlights

- Travels - X Axis Travel distance (mm): 550

- Travels - Y Axis Travel distance (mm): 400

- Travels - Z Axis Travel distance (mm): 450

Series description

|

The DEM Series is a vertical machining center designed for 3-axis general machining with a high-rigidity structure. This model is optimized for delivering the essential performance required for basic cutting processes, making it highly suitable for a wide range of machining tasks. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 550 |

|---|---|

| Travels - Y Axis Travel distance (mm) | 400 |

| Travels - Z Axis Travel distance (mm) | 450 |

| Travels - Z Axis Rapid Traverse (m/min) | 24 |

Feed rates

| Feed rate - X Axis Rapid Traverse | 24 |

|---|---|

| Feed rate - Y Axis Rapid Traverse | 24 |

| Feed rate - Z Axis Rapid Traverse | 24 |

Table

| Table Length (mm) | 650 |

|---|---|

| Table Width (mm) | 400 |

| Max. Workpiece weight (kg) | 400 |

| Pallet Size (mm) | 650x400 |

| Max. Table weight (kg) | 400 |

Workpiece capacity

| Max. Workpiece Height (mm) | 500 |

|---|---|

| Max. Workpiece weight (kg) | 400 |

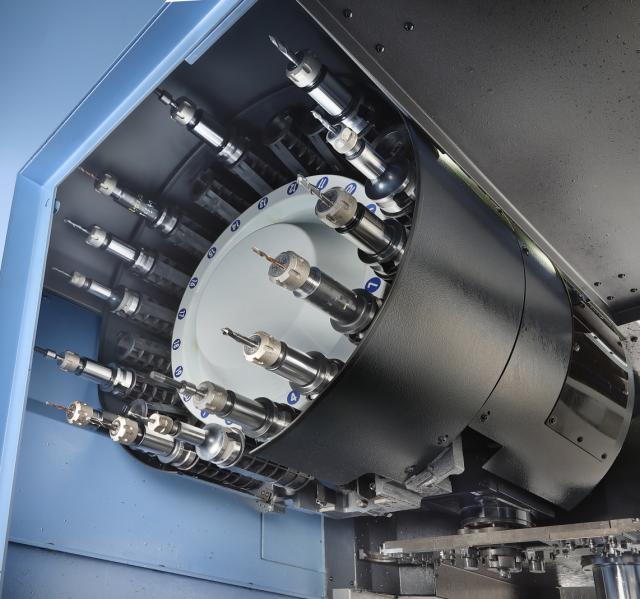

Tool storage capacity

| Machining center - No. of tool station | 20 |

|---|

Capacity

| Table to spindle nose | 570 |

|---|

Main spindle

| Main Spindle Max. Speed | 8000 |

|---|---|

| Main Spindle Max. Power | 5.5 |

| Main Spindle Max. Torque | 47.7 |

| Tool Taper (ISO) | 40 |

Turret

| Turret - No. of tool station | 20 |

|---|

Dimensions

| Length (mm) | 1875 |

|---|---|

| Height (mm) | 2317 |

| Width (mm) | 2200 |

| Weight (kg) | 3100 |

| Name | Download | File type | |

|---|---|---|---|

|

DEM 4000.pdf | 3850 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |

Contact us

If you have any questions, don't hesitate to contact us.