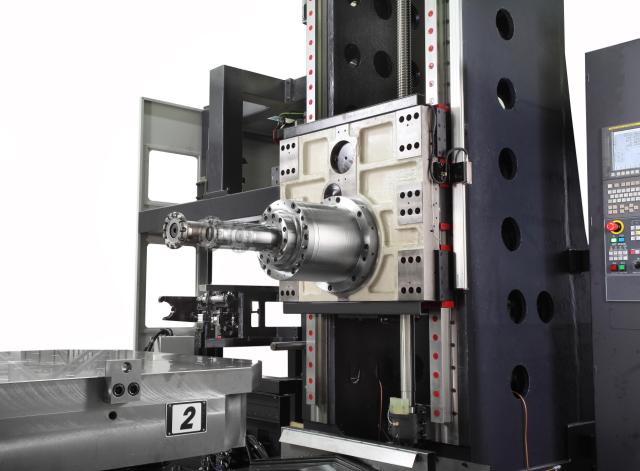

HM 1250

- Versatile Machining: Accommodates large workpieces with 1000/1250mm pallets and optional W-axis for a wide range of applications.

- High Productivity: Heavy-duty box guideways and high-torque gearbox spindle maximize cutting efficiency and output.

- Minimized Downtime: Designed to reduce non-cutting time, enhancing overall productivity and value.

Highlights

- Travels - X Axis Travel distance (mm): 2100

- Travels - Y Axis Travel distance (mm): 1500

- Travels - Z Axis Travel distance (mm): 1500

Series description

|

The HM Series is a twin-pallet horizontal machining center specifically designed for processing large workpieces. With a 1000/1250mm pallet size and optional W-axis capability, it supports a wide range of machining applications. The series features heavy-duty box guideways, a high-torque gearbox spindle, and minimized non-cutting time, ensuring exceptional productivity and added value for users. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 2100 |

|---|---|

| Travels - Y Axis Travel distance (mm) | 1500 |

| Travels - Z Axis Travel distance (mm) | 1500 |

Feed rates

| Feed rate - X Axis Rapid Traverse | 24 |

|---|---|

| Feed rate - Y Axis Rapid Traverse | 24 |

| Feed rate - Z Axis Rapid Traverse | 24 |

Table

| Table Length (mm) | 1250 |

|---|---|

| Table Width (mm) | 1250 |

| Max. Workpiece weight (kg) | 3000/5000 |

| Pallet Size (mm) | 1250X1250 |

| Rotary Table Diameter (mm) | 1250X1250 |

| Max. Table weight (kg) | 3000/5000 |

Workpiece capacity

| Max. Workpiece Diameter (mm) | 2000/2300 |

|---|---|

| Max. Workpiece Height (mm) | 1725 |

| Max. Workpiece weight (kg) | 3000/5000 |

Tool storage capacity

| Machining center - No. of tool station | 60/90/120/196/256/316 |

|---|

Capacity

| Table to spindle nose | 1575 |

|---|

Main spindle

| Tool Taper (ISO) | 50 |

|---|

Dimensions

| Length (mm) | 10530 |

|---|---|

| Height (mm) | 4060 |

| Width (mm) | 5822 |

| Weight (kg) | 31000 |

| Name | Download | File type | |

|---|---|---|---|

|

HM_1000_1250_1250W .pdf | 3470 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |

Contact us

If you have any questions, don't hesitate to contact us.